⇒ Liquid Tranfer Pump

LOBE PUMP

METERING PUMP

BARREL PUMP ( Operated by - Electrically, Air & Hand )

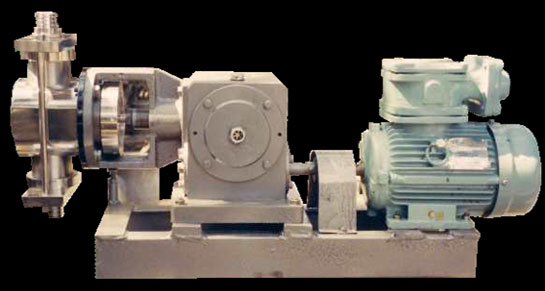

⇒ Lobe Pump

How Lobe Pumps Work

How Lobe Pumps Work

Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

1. As the lobes come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate.

2. Liquid travels around the interior of the casing in the pockets between the lobes and the casing -- it does not pass between the lobes.

3. Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other PD types. Since the lobes do not make contact, and clearances are not as close as in other PD pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids

Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other PD types. Since the lobes do not make contact, and clearances are not as close as in other PD pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids

- Material of Constructions – SS 304,304L,316

- Inlet & Outlet – as per Client Requirement with TC

- Capacity Kg/Hr – 100 to 1000 Kg/Hr.

- Liquid to be Handle – Name and Vicsosity.

- Pressure & Temprature

- Seal with Recommended Motor

⇒ Metering Plunger Type Pump

Product Description:

Product Description:

Backed by a state of the art infrastructure, we have become a major names of a wide range of Metering Plunger Type Pump. This pump is checked under the guidance of our experts. It is provided to our clients at nominal rates

Features

- High strength

- Easy installation

- Sturdy construction

⇒ Barrel Pump

| HAND OPERATED PUMP Rotary : Stainless Steel 316 Available in SS 316 / SS 304 Construction Vanes & Seals are made of Teflon Inlet & Outlet Size : 1” Dual Thread Adopter for Steel and Plastic Drums Suitable for Chemicals and Solvents & Aroma Oils Standard Length - 990 MM Output : 200 ML / Rotation Maximum Head : 5 Mtrs Viscosity : Max 800 CPS |

Polypropylene Pump Available in Polypropylene Construction Vanes & Seals are made of Teflon Inlet & Outlet Size : 1” Dual Thread Adopter for Steel and Plastic Drums Suitable for Strong Acids Standard Length - 990 MM Output : 200 ML / Rotation Maximum Head: 5 Mtrs Viscosity : Max 800 CPS |

High Flow, Lobe Type Available in Aluminum Construction Inlet & Outlet Size : 40 MM Dual Thread Adopter for Steel and Plastic Drums. Suitable for Lubricating Oils, Resins, Petrol and Diesel. Standard Length - 990 MM Output : 1 Ltr / Rotation. Maximum Head : 20 Mtrs Viscosity : Max 2000 CPS |

| MOTORISED DRUM PUMP Stainless Steel 316 Low Viscous Pump Suitable for all types of thin bodied liquids Empties the drum to residue of 1 Litre Flow Rate - Max 80 LPM Max Head - 12 Mtrs Standard Tube Inlet - 44 MM. Outlet - 20 MM Standard Tube Length is 1000 MM Custom Lengths up to 2000 MM Max Viscosity - 200 CPS |

Accessories Hand Flow Regulator SS Braided Hose Wall Bracket Drive Motors - Electrical Motor Non Flameproof / Flameproof Single Phase Motors 350 Watts / 700 Watts 220 Volt / 50 - 60 Hz On - Off Switch with 5 Mtr Long Electrical Cord Intermittent Duty Rated. Can run up to 40 Minutes |

Stainless Steel 316 High Viscous Pump Suitable for Low and High Viscous Liquids / Paste / Cream Flow Rate - Max 50 Kgs / Minute Pumps with various Flow Rate Available Flow Rate depending upon Viscosity Standard Discharge Pressure - 8 Bar Max Discharge Pressure -12 Bar SS 316 ROTORS STATORS available in Viton,H ypalan, EPDM,B una-N , H i N itrile Standard Tube Inlet - 44 MM. Outlet - 40 MM Standard Tube Length is 1000 MM Custom Lengths up to 1500 MM Max Viscosity - 20000 CPS |

Drive Motors - Electrical Motor Single and Three Phase, TEFC, Non Flameproof Motors Three Phase, TEFC, Flameproof Motors Standard Speed 960 RPM Motor HP depends on Liquid Viscosity & Head Requirement Motors are Induction Type, Continuous Duty Rated |

| LOW VISCOUS TYPE Air Operated Low Viscous Pump Suitable for Flameproof Applications Flow Rate - Max 80 LPM. Max Head - 12 Mtrs. Air Inlet Size - ¼ “. Air Pressure requirement 4 - 6 Bar. Air Motor is a Variable Speed Drive. Flow Rate and Head varies with Air Pressure & Air Consumption. Air Consumption - 18 CFM. Automatically cools down. Continuous Duty Rated. Max Viscosity - 700 CPS As sparking or fusing is not possible, Air Motor offers explosion protection without involving additional cost for safety precaution |